Zinc Corrosion Anodes

SHIP PROTECTION: ZINC CATHODIC ANODES PREVENTS CORROSION

When it comes to materials exposed to water, certain metals will corrode faster than others. This problem is serious for ships that are out in freshwater or saltwater environments. Iron metal is used extensively throughout a ship, from the hull’s body to mechanical equipment, as this material is the most corrosion-prone metal. Other metals also experience corrosion as they are impacted at various levels even when not in direct contact of the water. Moisture-laden winds can also cause metal corrosion on ships, dock gates, platforms, storage tanks and other structures.

There are several ways to protect a ship from this corrosion. In addition to using paints with anti-corrosion qualities, Zinc cathodic anodes will help prolong the life of metal used in marine applications.

What are Cathodic Anodes?

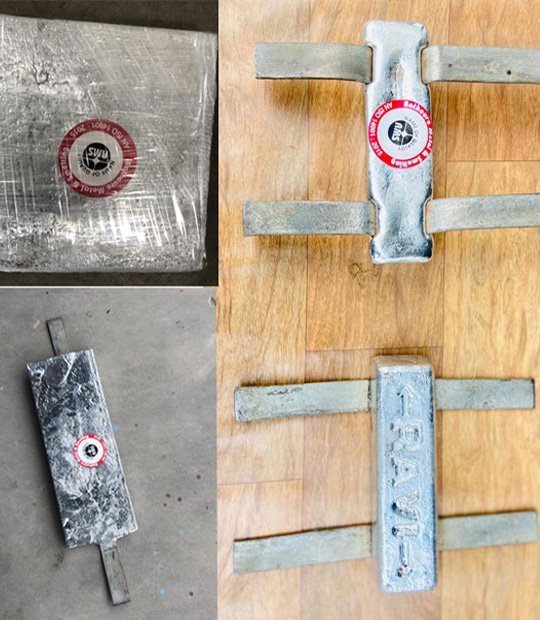

Cathodic anodes are strips of metal that are attached to another piece of metal that will experience corrosion due to maritime environments. The ship’s metal, the salt water, the oxygen and hydrogen in the water, and the anode are turned into an electrochemical cell. An electrical current becomes generated as the metal strip is turned into a cathodic anode due to its inherent electrical efficiency. The electrons in the metal are drawn out of it into the water, as this creates corrosion.

Since the cathodic anode contains a higher electrical efficiency than the metal it is attached to, the electrons are pulled first from the cathodic anode instead of the ship’s metal. This process is called cathodic protection, as the anode experiences the corrosion activity instead of the ship. Cathodic anodes are also called sacrificial anodes because they “sacrifice” themselves to the water to protect the metal that the anode is attached to.

How does a zinc anode protect from corrosion?

A zinc anode’s protective properties result from a strongly negative reduction potential, which is more negative than the metal it is protecting. Oxidants, which corrode metals, will oxidize the zinc anode rather than the protected metal structure, thus preventing the structure from being corroded.

Leading Electroplating Anodes Manufacturer in India

Your Source for

Chrome Plating Anodes, Solder wire, Lead Tin Anodes and Zinc Alloy